| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : BLOOM

Place of Origin : Jiangsu, China (Mainland)

MOQ : 1set

Price : Negotation

Payment Terms : Western Union, L/C, T/T

Supply Ability : 2000pc/pcs per Month

Delivery Time : 5-10 days subject to the clients' requirement and quantity

Packaging Details : packed and labeled according to the regulations and customer's requests.Great care is taken to avoid any damage which might otherwise be caused during storage or transportation.

Place of origin : Jiangsu,China

Material : 38CrMoAIA

Spare parts : spare parts for screw extruders

Center distance : 26mm

Dimension : 120x135x115mm

After warranty : Video technical support ,online support

Nitride And Bimetallic Screw Barrel Solution Extending The Service Life

Description:

Screw and barrel produced by BLOOM are all have quenching and nitride process. We have

been dedicated ourselves to find method of anti-corrosion and anti- abrasion.

1. The steel we use to manufacture screw and barrel is 38 CrMoAl.

2. Nitride and quenching process:

Hardness after quenching: HB280-320

Hardness after nitride :> HV950

Nitride depth: 0.5mm-0.8mm

3. Bimetallic screw barrel

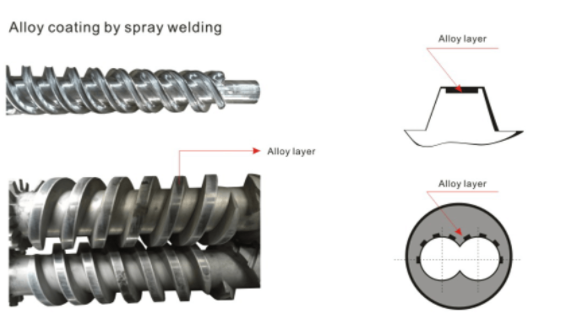

A. The flights of screw are grooved and bimetallic layer is coated by spray wielding method.

Nickel based alloy powder is applied.

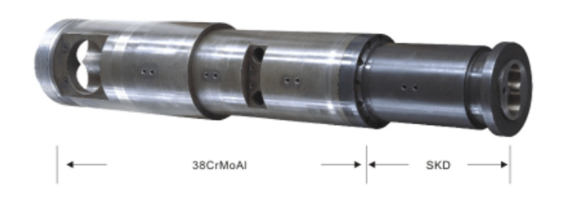

B. SKD 61 is a kind of steel imported from Japan which is even more durable than normal bimetallic barrel. We use SKD steel to the wearing part of barrel as shown in the below picture. This high cost application is usually required in formulations with high percentage of fillers such as calcium and glass fiber or WPC.

Application:WPC

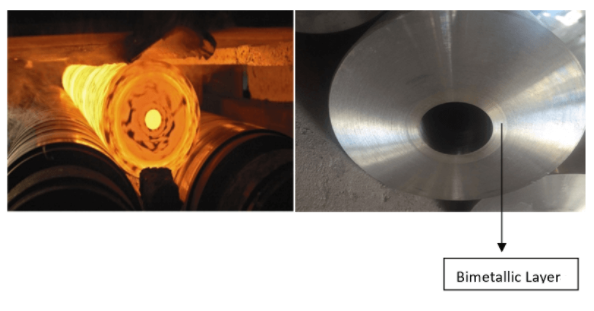

C.Spin casting (Applied in single barrel)

Spin casting coating method is used in single barrel as shown below.

|

|

Nitride And Bimetallic Screw Barrel 38CrMoAIA For Extruders Images |